Brass Plating

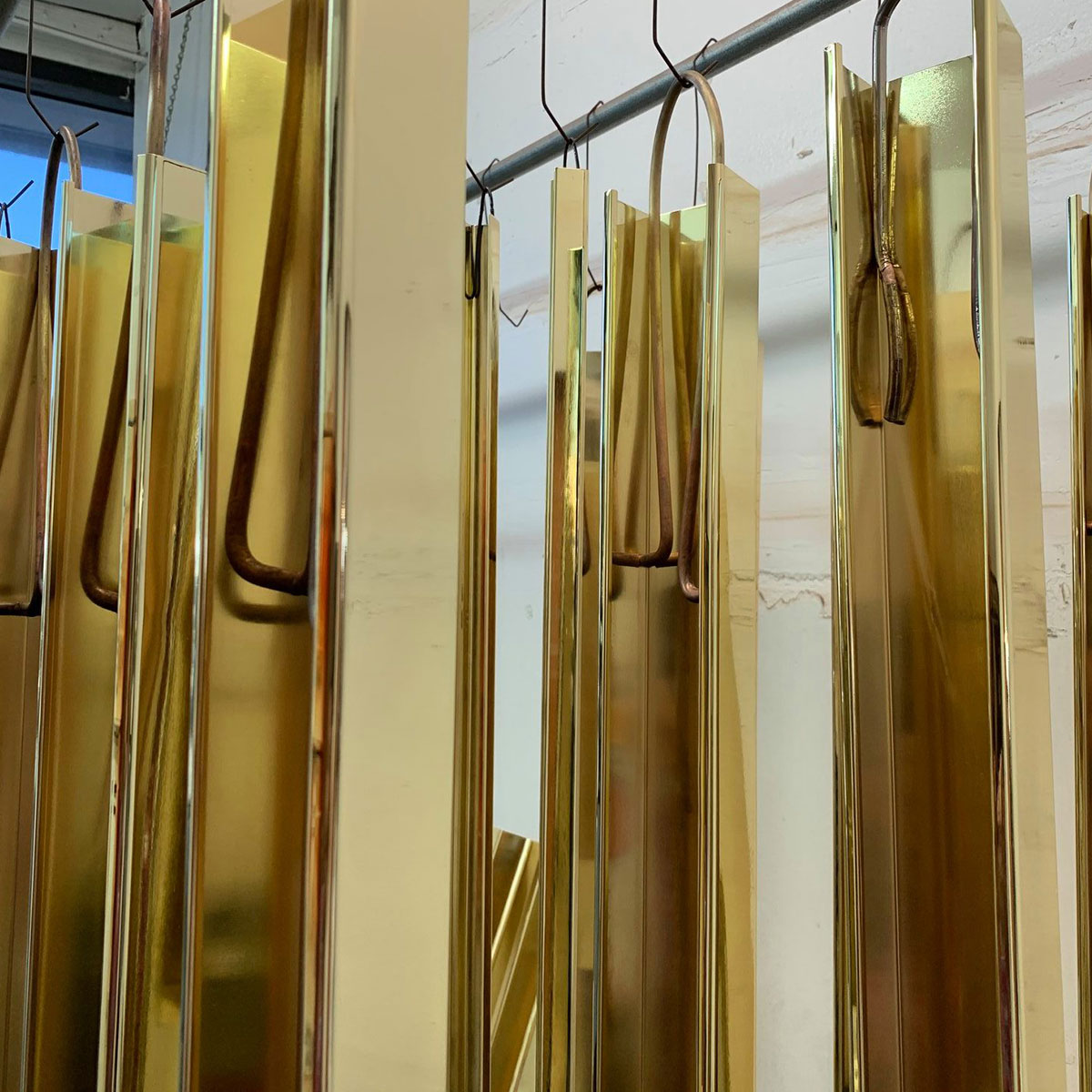

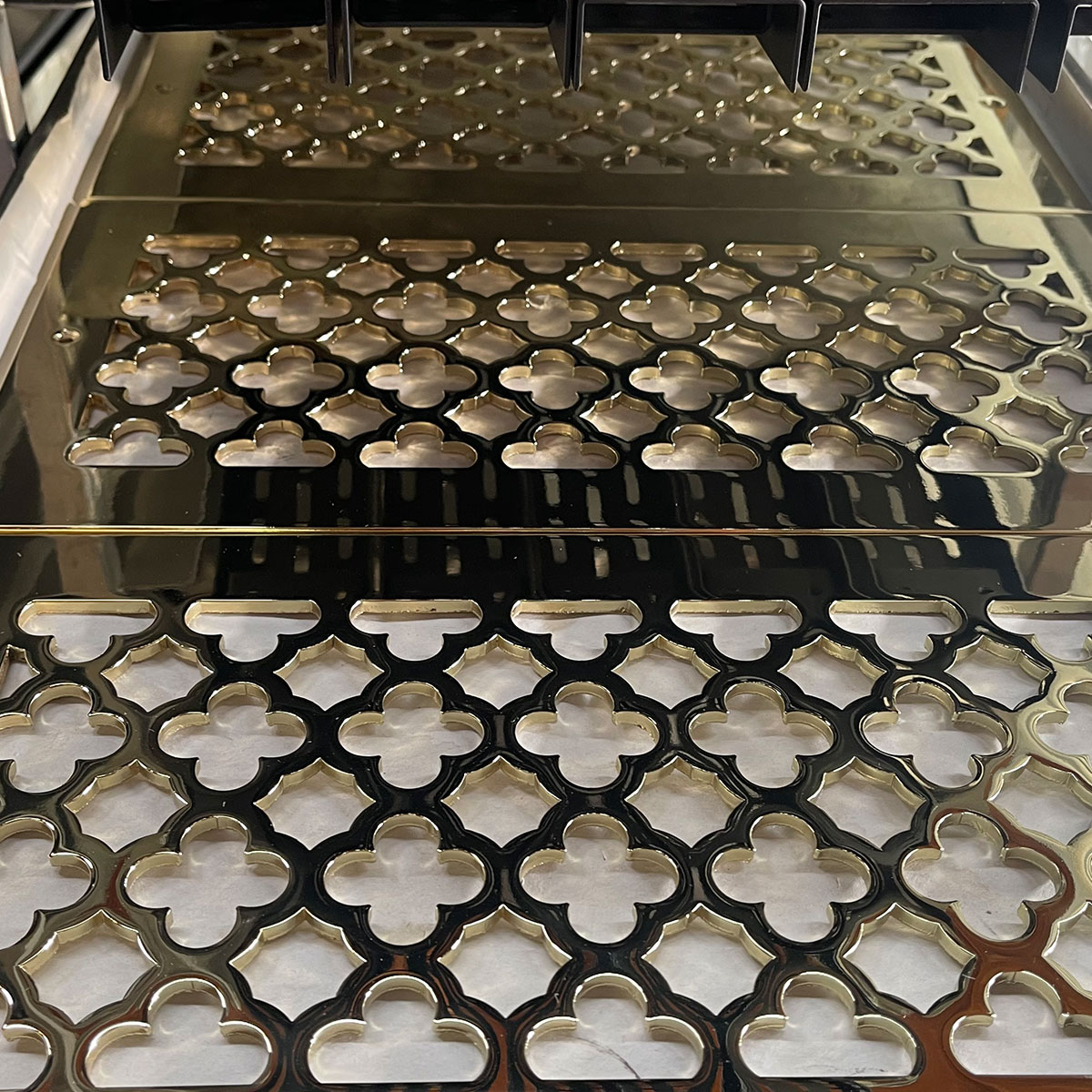

Brass Plating adds a touch of timeless elegance to your products

Whether you're a manufacturer seeking to enhance your product line or a designer looking to realize your vision, our state-of-the-art facilities and expert team are here to bring your ideas to life. Explore our comprehensive Brass plating solutions and take your products to the next level of excellence.

Request a Quote!Brass Plating Process

This concise list provides an overview of the brass plating process, offering insight into each step involved in achieving high-quality brass-plated finishes.

Preparation: The surface to be plated is thoroughly cleaned and degreased to ensure proper adhesion of the brass coating.

Surface Activation: The surface is activated using a specific chemical solution or through electrocleaning, which helps remove any remaining contaminants and prepares the substrate for plating.

Electroplating Bath Preparation: A solution containing brass ions is prepared in an electroplating bath. This bath typically consists of a brass salt dissolved in water along with other additives to control the plating process.

Immersion in Electroplating Bath: The cleaned surface is immersed in the electroplating bath. When an electric current is applied, brass ions in the solution are attracted to the surface of the substrate, forming a thin layer of brass coating.

Electroplating Process: An electric current is passed through the electroplating bath, causing the brass ions to deposit onto the surface of the substrate, gradually building up the desired thickness of the brass plating.

Rinsing: Once the desired thickness of brass plating is achieved, the plated object is removed from the electroplating bath and rinsed thoroughly to remove any residual plating solution.

Drying: The plated object is then dried using air or other drying methods to ensure the brass plating is fully set and any remaining moisture is removed.

Finishing Touches: Depending on the desired finish, the brass-plated object may undergo additional processes such as buffing, polishing, or applying a protective clear coat to enhance its appearance and durability.

Brass Plating Benefits for Manufacturers:

By leveraging our brass plating service, wholesale businesses and manufacturers can enjoy these benefits and gain a competitive edge in their respective industries, ultimately enhancing the quality and appeal of their products.

Enhanced Aesthetics: Brass plating adds a luxurious and aesthetically pleasing finish to products, elevating their appearance and appeal to customers. Whether it's enhancing the look of hardware, fixtures, or decorative items, brass plating brings a touch of elegance and sophistication.

Corrosion Resistance: Brass plating provides a protective barrier against corrosion and oxidation, extending the lifespan of products exposed to harsh environments or moisture. This corrosion resistance is particularly beneficial for manufacturers producing outdoor or marine equipment, ensuring durability and longevity.

Versatility: Our brass plating service is highly versatile, accommodating a wide range of substrates including steel, aluminum, copper, and various alloys. This versatility enables manufacturers to apply brass plating to diverse products across industries such as automotive, electronics, plumbing, and jewelry.

Customization Options: With our brass plating service, wholesale and manufacturers can customize the finish to meet their specific design requirements. Whether it's achieving a polished, satin, or antique brass finish, our skilled craftsmen can tailor the plating process to match the desired look and feel of the product.

Cost-Effectiveness: Brass plating offers a cost-effective alternative to solid brass components, allowing manufacturers to achieve the desired aesthetic at a fraction of the cost. This cost savings can be significant for wholesale businesses and manufacturers seeking to maintain competitive pricing without compromising on quality.

Increased Marketability: Products featuring brass plating often command higher perceived value in the market, translating into increased sales and profitability for wholesale businesses and manufacturers. The luxurious appearance and durability of brass-plated products can attract discerning customers and drive demand for their offerings.

Environmental Sustainability: Our brass plating process adheres to environmentally friendly practices, utilizing eco-conscious solutions and minimizing waste generation. Wholesale businesses and manufacturers can align with sustainability goals and appeal to environmentally conscious consumers by opting for our environmentally responsible plating service.

Applications of Our Brass Plating

Our Brass Plating service for these diverse applications, industries and manufacturers can enhance the appearance, functionality, and durability of their products, catering to the needs and preferences of their target markets with style and reliability.

Decorative Hardware: Brass plating adds a touch of elegance to decorative hardware such as handles, knobs, hinges, and fixtures. Whether it's for furniture, cabinetry, or architectural elements, brass-plated hardware enhances the overall aesthetics and sophistication of the finished product, elevating its visual appeal.

Automotive Components: Brass plating is widely used in the automotive industry for various components such as emblems, trim, grilles, and interior accents. The luxurious appearance and corrosion resistance of brass-plated parts enhance the interior and exterior aesthetics of vehicles, contributing to a premium look and feel.

Electronic Enclosures: Brass plating offers excellent conductivity and corrosion resistance, making it an ideal choice for electronic enclosures, connectors, and components. The brass coating not only provides protection against environmental factors and wear but also improves the electrical performance and reliability of electronic devices.

Jewelry and Accessories: Brass plating is commonly utilized in the jewelry and accessories industry for creating stylish and affordable pieces. From bracelets and earrings to buckles and belt accessories, brass-plated jewelry and accessories offer a trendy and fashionable alternative to solid brass or gold items, appealing to a wide range of consumers.

Lighting Fixtures: Brass-plated lighting fixtures exude a warm and inviting glow, making them a popular choice for residential and commercial lighting applications. Whether it's chandeliers, sconces, or pendant lights, brass-plated fixtures add a touch of sophistication and elegance to any space, enhancing the ambiance and décor.

Plumbing Fixtures: Brass plating is often used in plumbing fixtures such as faucets, showerheads, and valves due to its corrosion resistance and durability. Brass-plated plumbing fixtures not only withstand the rigors of daily use and exposure to water but also enhance the aesthetic appeal of kitchens and bathrooms, adding a luxurious finishing touch.

Musical Instruments: Brass plating is employed in the manufacturing of musical instruments such as trumpets, trombones, and saxophones, where it serves both aesthetic and functional purposes. Brass-plated instruments not only look visually striking but also offer enhanced durability and corrosion resistance, ensuring optimal performance and longevity.

Brass Plating FAQs

What is brass plating, and how does it work?

Brass plating is a process where a thin layer of brass is deposited onto a substrate through electroplating. It involves immersing the cleaned surface into an electroplating bath containing brass ions, which are attracted to the substrate when an electric current is applied, resulting in a brass-plated finish.

What are the benefits of brass plating for industries and manufacturers?

Brass plating offers enhanced aesthetics, improved durability, and corrosion resistance for products. It adds value perception, customization options, and versatility in applications while being a cost-effective solution and environmentally sustainable.

What types of industries can benefit from brass plating services?

Industries such as automotive, electronics, furniture, jewelry, lighting, plumbing, and manufacturing can all benefit from brass plating services for various components and products.

How does brass plating enhance the aesthetics of products?

Brass plating adds a luxurious and sophisticated finish to products, elevating their visual appeal and creating a premium look. It can be customized to achieve different finishes like polished, satin, or antique brass, enhancing the overall aesthetics of the finished product.

Is brass plating durable and resistant to corrosion?

Yes, brass plating is known for its durability and resistance to corrosion. The brass coating acts as a protective barrier, shielding the substrate from environmental factors, moisture, and wear, thereby extending the lifespan of products.

Can brass plating be applied to different types of materials?

Yes, brass plating is versatile and can be applied to various substrates including steel, aluminum, copper, and different alloys, making it suitable for a wide range of applications across industries.

What customization options are available with brass plating?

Brass plating offers extensive customization options, allowing for different finishes such as polished, satin, or antique brass. Additionally, the thickness of the brass plating can be adjusted to meet specific design requirements.

Is brass plating cost-effective compared to using solid brass components?

Yes, brass plating provides a cost-effective alternative to solid brass components, allowing manufacturers to achieve the desired aesthetic at a fraction of the cost while maintaining high-quality standards.

How environmentally sustainable is brass plating?

Our brass plating process adheres to environmentally responsible practices, utilizing eco-friendly solutions and minimizing waste generation. By choosing our environmentally sustainable plating service, you can demonstrate your commitment to sustainability.

What industries can West Coast Plating serve with its brass plating services?

West Coast Plating caters to a wide range of industries including automotive, electronics, furniture, jewelry, lighting, plumbing, and manufacturing, providing brass plating solutions for diverse applications and components.