Chrome Plating

Your Trusted Chrome Plating Partner

At West Coast Plating, we understand the needs of high-volume producers. We offer reliable, efficient chrome plating services specifically tailored to meet the demands of wholesale and manufacturers across a wide range of industries.

Request a Quote!Chrome Plating Process

This comprehensive overview of the Chrome Plating Process highlights the meticulous steps involved in achieving high-quality chrome-plated finishes, ensuring durability, aesthetics, and performance for a wide range of industrial and consumer applications.

Surface Preparation: The process begins with thorough cleaning and preparation of the metal substrate to remove any dirt, grease, or old coatings. This ensures proper adhesion and a flawless finish.

Degreasing: Metal parts are immersed in a degreasing solution or subjected to solvent cleaning to remove any residual oils or contaminants from the surface.

Surface Activation: The metal substrate is then subjected to a series of chemical baths to activate its surface, creating a receptive environment for the subsequent plating process.

Chrome Plating: The metal substrate is immersed in a bath containing chromium electrolyte, and an electric current is passed through the solution. This causes chromium ions to adhere to the surface of the substrate, forming a thin layer of chrome plating through electroplating.

Rinsing: After chrome plating, the parts are thoroughly rinsed to remove any residual plating solution or contaminants, ensuring a clean and smooth finish.

Drying and Inspection: Once rinsed, the chrome-plated parts are dried and inspected for uniformity, adhesion, and overall quality. Any imperfections are addressed to ensure a flawless finish.

Final Finishing: Depending on the desired appearance and specifications, additional finishing processes such as polishing, buffing, or coating may be applied to further enhance the aesthetics and functionality of the chrome-plated parts.

Packaging and Shipping: The finished chrome-plated parts are carefully packaged to protect them during transit and shipped to the customer, ready for use in various applications.

Chrome Plating Benefits for Manufacturers:

The benefits highlight the value that our Chrome Plating Service can offer to wholesale and manufacturers industries, enhancing both the functionality and aesthetics of their products while optimizing cost-efficiency and sustainability.

Enhanced Durability: Chrome plating provides a protective layer that enhances the durability of metal parts, making them less susceptible to corrosion, wear, and tear. This ensures that components maintain their integrity and functionality over an extended period, reducing the need for frequent replacements.

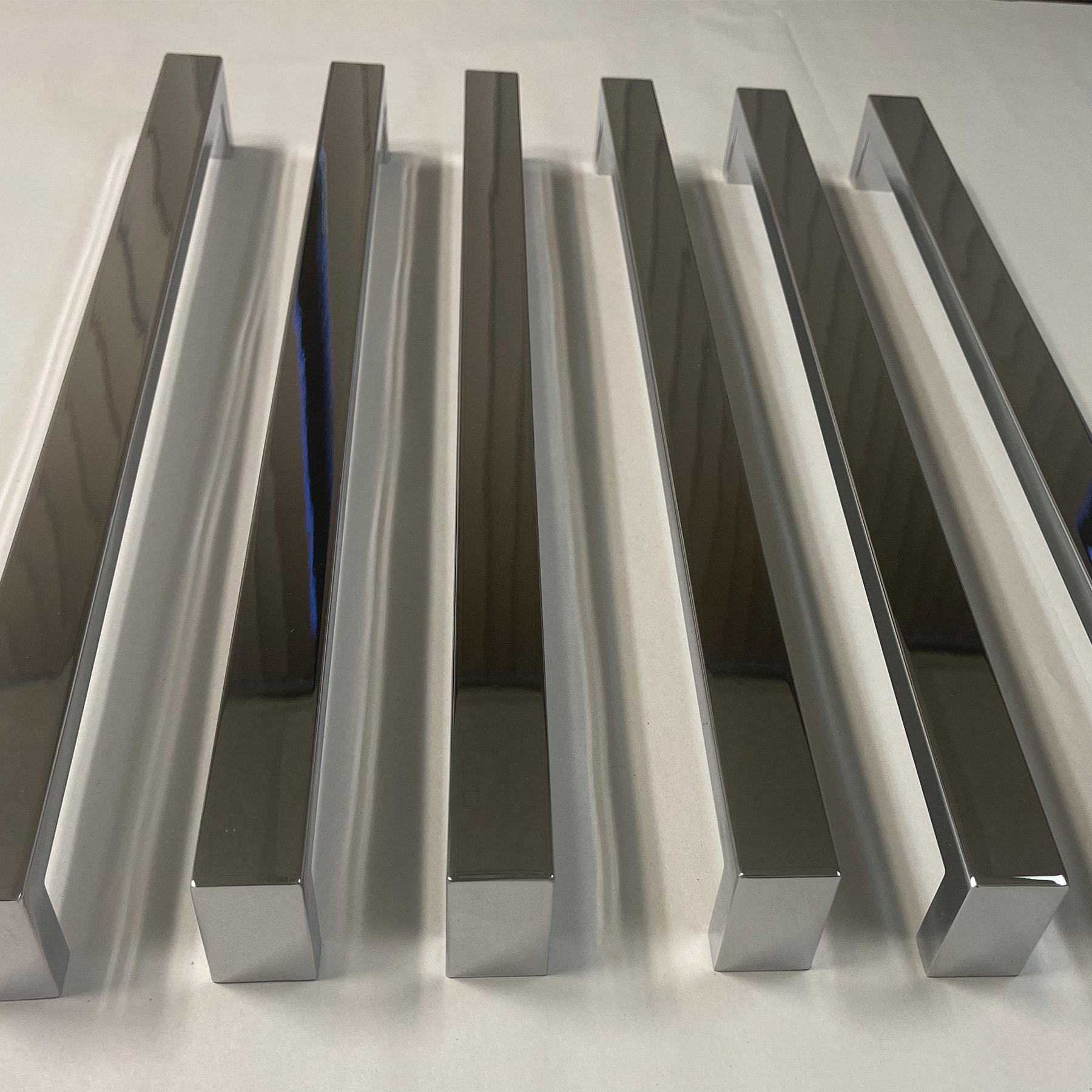

Improved Aesthetics: Our chrome plating service adds a lustrous finish to metal surfaces, enhancing their visual appeal. Whether it's automotive parts, industrial equipment, or consumer goods, chrome plating can elevate the appearance of products, contributing to a more polished and professional image.

Corrosion Resistance: Chrome plating creates a barrier against moisture, chemicals, and other environmental factors that can lead to corrosion. This is particularly beneficial for wholesale and manufacturing industries where metal components are exposed to harsh conditions or undergo frequent handling and transportation.

Increased Product Lifespan: By protecting metal parts from corrosion and wear, chrome plating helps extend the lifespan of products. This not only improves the reliability of goods but also enhances customer satisfaction by delivering long-lasting performance.

Customization Options: We offer customization options for chrome plating, allowing wholesale and manufacturers to tailor the finish to meet their specific requirements. Whether it's achieving a particular shine, texture, or color, our chrome plating service can accommodate diverse needs and preferences.

Cost-Effectiveness: Investing in chrome plating can be a cost-effective solution for wholesale and manufacturers industries. By extending the lifespan of metal components and reducing maintenance requirements, businesses can save on replacement costs and minimize downtime, ultimately improving their bottom line.

Environmental Sustainability: Chrome plating is known for its environmentally friendly properties, as it involves minimal waste and emissions compared to alternative coating methods. This makes it a sustainable choice for businesses looking to reduce their environmental footprint while maintaining high-quality finishes.

Applications of Our Chrome Plating

The diverse applications showcase the versatility and value of our Chrome Plating service for industries and manufacturers across various sectors, offering superior protection, aesthetics, and performance for a wide range of products and applications.

Automotive Components: Elevate the appearance and durability of automotive components with our Chrome Plating service. From bumpers and trim to wheels and exhaust systems, chrome plating adds a sleek, high-gloss finish that enhances the aesthetic appeal of vehicles while providing robust protection against corrosion and wear.

Industrial Machinery and Equipment: Enhance the performance and longevity of industrial machinery and equipment with our Chrome Plating service. From hydraulic cylinders and valves to gears and shafts, chrome-plated components withstand the rigors of heavy-duty applications, minimizing downtime and maintenance costs.

Aerospace and Defense Systems: Ensure the reliability and safety of aerospace and defense systems with our Chrome Plating service. Components such as landing gear parts, fasteners, and instrumentation benefit from the superior corrosion resistance and wear protection provided by chrome plating, ensuring optimal performance and longevity in aerospace and defense applications.

Marine Equipment and Hardware: Protect marine equipment and hardware from the corrosive effects of saltwater and harsh marine environments with our Chrome Plating service. From boat propellers and fittings to cleats and railings, chrome-plated surfaces resist corrosion and pitting, extending the lifespan of marine components and enhancing the appearance of vessels.

Consumer Goods and Appliances: Add value and appeal to consumer goods and appliances with our Chrome Plating service. From kitchen faucets and bathroom fixtures to electronic devices and household appliances, chrome-plated finishes create a polished, upscale look that enhances product aesthetics and perceived quality.

Decorative and Architectural Features: Beautify decorative and architectural features with our Chrome Plating service. From furniture hardware and lighting fixtures to door handles and signage, chrome-plated surfaces add a touch of elegance and sophistication to interior and exterior spaces. Our precision chrome plating process ensures flawless finishes that elevate the visual appeal of architectural designs and interior décor, creating lasting impressions in residential, commercial, and hospitality settings.

Electronics and Electroplating: Improve the performance and appearance of electronic components with our Chrome Plating service. From connectors and contacts to housings and bezels, chrome-plated surfaces provide electrical conductivity, corrosion resistance, and aesthetic enhancement for electronic devices and equipment.

Chrome Plating FAQs

What is chrome plating and how does it benefit metal components?

Chrome plating is a process where a thin layer of chromium is electroplated onto a metal surface. It provides several benefits including enhanced durability, corrosion resistance, and improved aesthetics, making metal components more resilient and visually appealing.

Which industries can benefit from West Coast Plating's services?

West Coast Plating serves a diverse range of industries including automotive, manufacturing, aerospace, marine, electronics, and consumer goods, among others. Our chrome plating solutions cater to various applications across different sectors.

What types of metal substrates can be chrome plated?

Our chrome plating process can be applied to a wide range of metal substrates including steel, aluminum, brass, copper, and various alloys. This versatility allows for consistent quality and performance across different materials.

How long does the chrome plating process take?

The duration of the chrome plating process can vary depending on factors such as the size and complexity of the parts, as well as the desired finish. Typically, the process may take several hours to complete, including preparation, plating, and finishing.

Is chrome plating environmentally friendly?

Yes, chrome plating is known for its environmentally friendly properties compared to alternative coating methods. Our process adheres to stringent environmental standards and regulations, minimizing waste and emissions for a more sustainable solution.

Can chrome-plated parts be customized to meet specific requirements?

Yes, we offer customization options for chrome-plated parts to meet our clients' specific design preferences and branding requirements. Whether it's achieving a particular shine, texture, or color, our chrome plating service can accommodate diverse needs and specifications.

How does chrome plating contribute to product longevity?

Chrome plating provides a protective layer that enhances the durability of metal components, making them less susceptible to corrosion, wear, and tear. This extends the lifespan of products, reducing the need for frequent replacements and repairs.

What maintenance is required for chrome-plated parts?

Chrome-plated parts require minimal maintenance due to their resistance to dirt, grime, and stains. Regular cleaning with mild soap and water is usually sufficient to keep the surface looking pristine. Avoid harsh abrasives or chemicals that may damage the chrome finish.

Can chrome plating be applied to both small and large-scale projects?

Yes, our chrome plating services are scalable and can be applied to both small and large-scale projects. Whether you need a single prototype or bulk production, we have the capabilities and expertise to fulfill your requirements with precision and efficiency.

What sets West Coast Plating apart from other chrome plating providers?

West Coast Plating stands out for its commitment to quality, craftsmanship, and customer satisfaction. With decades of experience and a dedication to excellence, we deliver superior chrome plating solutions that exceed expectations, ensuring the success of our clients' projects.